Advanced Designs For EMC Compliance

All Printed Circuit Boards (PCBs) must be able to function without disruption because of interference from other circuits, gadgets or electronic equipment. They should also not cause interference themselves so that they can provide a conducive operating environment for other devices in the vicinity.

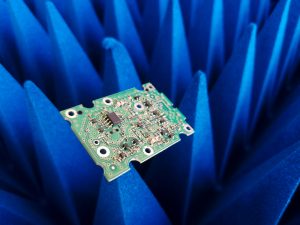

To achieve this, PCBs need to undergo EMC (Electromagnetic Compatibility) testing during the design and building phases of production. EMC testing and compliance is what keeps our gadgets from constantly interfering with each other.

With proper design, you can pass EMC compliance testing without any problems. It’s not uncommon for manufacturers to wait until they have finished assembling a device to perform EMC testing which is wrong. Making EMC considerations after a circuit board has already been developed can cost you significant amounts of time and money.

Design For EMC Compliance

Building electronic circuits with EMC in mind from the very beginning can help you avoid costly mistakes in the future. Below are some advanced EMC design techniques that can help you get EMC compliance more easily and quickly.

Board Layouts

It’s crucial to consider the signals that will be produced by your PCB. Some of these signals will be necessary, but a huge majority of EMI signals on your circuit board that is produced will be unnecessary. Some of these unnecessary signals (emissions) will come from power planes, I/O traces, crosstalk coupling, and common-mode currents. Most radiated emissions will emanate from cables. So, how do you fix this problem with advanced EMC design?

When designing your traces, it’s important to reduce the number of loop sections for high-frequency power currents and signals. High-frequency currents and signals go back to their source which creates loops. With that in mind, the best way to reduce EMI when designing your board layout is to

– Increase trace width where possible.

– Fill your bottom and top layer with a solid ground plane to shield your inner layers from radiation.

– Incorporate stitching vias between layers and close to high-speed signals to keeps loops as tiny as possible.

– Avoid 90-degree angles for high-speed applications.

Filters

Filters can come in handy particularly for low-frequency signal lines like power input cables. In such cases, EMI filters can eliminate the high-frequency elements so that you are only left with low frequencies on the line that produces less radiation.

Filters should be installed at the entry point between the device and its environment, fixed properly to the body. This placement makes sure that no signals enter the equipment. Filters can also be placed in between the boards of a module or between isolated sections of your PCB.

Circuit Partitioning

Circuit partitioning is extremely important and should be done properly because it influences the entire map of the PCB. Moreover, it helps you organise your board so that you can choose the best placement for both low-noise and high-noise circuits in order to mitigate interference from the onset.

Circuit portioning enables you to separate the board into non-essential and essential areas. Essential areas are those that contain a source of EMI or may be susceptible to it, including high-speed microprocessor circuits, low-level analogue circuits, and high-frequency circuits. Through partitioning, you can incorporate filters and screens to protect these areas from the effects of EMI.

Grounding

Poor grounding can negatively impact the performance of your board. It can cause ground loops that produce radiated signals or emissions within the device. A grounding system provides a path for the current to return to its sources. A good system should be as direct as possible and have low impedance.

Many considerations are made when designing a PCB, but EMC design is among the most crucial. Using the advanced EMC designs listed above can help you achieve EMC compliance without a lot of trouble.

Compliance Engineering offers accredited testing services for a broad range of products in particular compliance with EMC regulations in Australia. We provide the highest standard of environmental testing that measures the performance of specific products under particular environmental conditions.

Please call us today at Compliance Engineering on + 61 3 9763 3079 or leave an enquiry.